Introduction of Aluminum PCB

Definition:

Aluminium PCB, also named aluminum base PCB, metal clad(MCPCB) PCB, insulated metal substrate(IMS or IMPCB) PCB, thermally conductive PCBs, etc. It is generally including single layer, double layer and multi layer.

Operating theory:

The power device surface mounting on circuit layer, it is ideally suited for the mounting of high power light emitting diodes (LEDs) easily dissipating the heat generated by power devices.

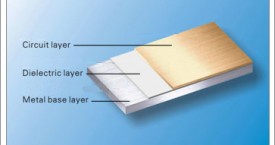

Compose:

Aluminum PCB consist of line layer, insulating layer, metal substrate.

Characteristic:

Aluminum PCB have good thermal Conductivity, and for aluminum base material can support strong enough electric current compared with FR-4 material. Aluminum PCB use SMT is very effective to deal with heat diffusion. And can reduce product volume, then decrease the cost of hardware and assembly. Lastly, it can low the product operating temperature and then lengthen its servise life.

Application:

Aluminum PCB use in audio device, electrical power unit, communication electronic equipment, automobile, computer, Power Module, LED. The application is very wide range

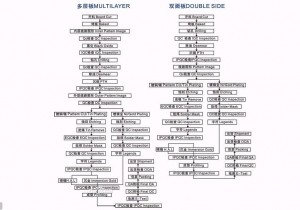

Technological process:

1) Board cut

2) Drilling

3) Wet/dry film imaging

4) The acidic/alkaline etching

5) Silkscreen, solder mask

6) V-cut, ROT

7) Testing, OSP

8) FQC-FQA-packing- shipment

Summary :

Ezpcb can do 1layers, 2 layer, Multi layer aluminum PCB. And the surface finish can be Gold plating, HASL, Lead Free, OSP. The min hole size can be 0.2mm( 8mil). 1 oz , 2 oz , 3 oz copper thickness is available.

Ezpcb also can provide proto type produce quickly and bulk production. The express is can be meet need. The lowest price is competitive and quality is guaranteed.