Introduction of Flex PCB

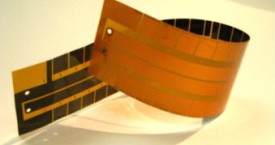

Flexible PCB, also known as FPC (flex printed circuit board), is a technology for assembling electronic circuits by mounting electronic devices on flexible plastic substrates, such as polyimide, PEEK or transparent conductive polyester[1] film. Additionally, flex circuits can be screen printed silver circuits on polyester. Flexible electronic assemblies may be manufactured using identical components used for rigid printed circuit boards, allowing the board to conform to a desired shape, or to flex during its use. These flexible printed circuits (FPC) are made with a photolithographic technology. An alternative way of making flexible foil circuits or flexible flat cables (FFCs) is laminating very thin (0.07 mm) copper strips in between two layers of PET. These PET layers, typically 0.05 mm thick, are coated with an adhesive which is thermosetting, and will be activated during the lamination process. FPCs and FFCs have several advantages in many applications:

- Tightly assembled electronic packages, where electrical connections are required in 3 axes, such as cameras (static application).

- Electrical connections where the assembly is required to flex during its normal use, such as folding cell phones (dynamic application).

- Electrical connections between sub-assemblies to replace wire harnesses, which are heavier and bulkier, such as in cars, rockets and satellites.

- Electrical connections where board thickness or space constraints are driving factors.

Flex Structures

- Single Side FPC: Single-sided flexible circuits have a single conductor layer made of either a metal or conductive (metal filled) polymer on a flexible dielectric film.

- Double access or back bared flex circuits: Double access flex, also known as back bared flex, are flexible circuits having a single conductor layer but which is processed so as to allow access to selected features of the conductor pattern from both sides.

- Sculptured flex circuits: Sculptured flex circuits are a novel subset of normal flexible circuit structures.

- Double-sided flex circuits: Double-sided flex circuits are flex circuits having two conductor layers. Theses flex circuits can be fabricated with or without plated through holes, though the plated through hole variation is much more common.

- Multilayer flex circuits: Flex circuits having three or more layers of conductors are known as multilayer flex circuits. Commonly the layers are interconnected by means of plated through holes.

- Rigid-flex circuits: Rigid-flex circuits are a hybrid construction flex circuit consisting of rigid and flexible substrates which are laminated together into a single structure.

- Polymer thick film flex circuits:Polymer thick film (PTF) flex circuits are true printed circuits in that the conductors are actually printed onto a polymer base film.